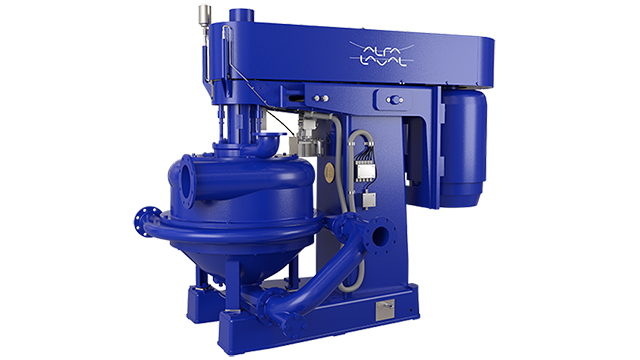

Merco

Alfa Laval Merco nozzle centrifuges are designed specifically to meet the separation needs of companies involved in starch processing. Built to cope with high solids loads, with a focus on better performance, low energy consumption and easy maintenance.

The Merco range of separators are different from conventional multi-purpose nozzle centrifuges, specially developed to meet starch processing requirements. These involve high solids loads and continuous discharge, combined with a need to avoid nozzle blockages.

Merco nozzle centrifuges are now widely used in the starch industry for processes that include primary starch separation, gluten thickening, mill stream thickening and the clarification of middlings. As part of this, they are used for classifying, concentrating and washing solids, and for clarifying liquids that contain relatively high concentrations of solids.

The key feature of the Merco design is a special recirculation system in which solids can be recirculated to the nozzles at the edge of the bowl, at the same time as wash water is added. This unique capability means users can adjust production settings while the system is in operation, simply by varying the nozzle draw-off.

The operator can change the split and the concentration by a simple adjustment of the underflow draw-off valve in the discharge line. This provides a uniquely efficient way to control the separation process by determining exactly how much underflow is to be removed, how much is to be recycled back to the rotor and how much wash water is to be added.

This also makes it possible to use large-diameter nozzles that can deal with variations in feed concentration, as well as helping prevent blockages. This in turn makes the unit more versatile, and makes it easy to vary procedures based on the characteristics of individual feed flows.

A wide range of different Merco models is currently available, with capacities of up to 1,000 tons per day.

Πως δουλεύει

The disc stack centrifuge at the heart of the Merco design employs centrifugal forces of up to 10,000 G to force the denser solids in a feed flow outwards against the bowl wall, while the less dense liquid phases form concentric inner layers. Special “disc stack” plates provide additional surface area for these solids to settle on, speeding up separation dramatically. The two different liquid phases meet at the interface position. To achieve concentration and separation with maximum efficiency, Merco centrifuges feature over-sized nozzles and larger openings between the discs.

The bowl is driven by a vertically mounted motor, via two bound V-belts. A large number of nozzles are placed around the periphery of the bowl, at a narrow angle from the tangent, in order to recover energy from the material being discharged through the nozzles. These nozzles are made of tungsten carbide, so they can withstand the effects of abrasive solids. The Merco centrifuge is also equipped with sensors for monitoring a wide range of different parameters, including bowl speed, vibration and bearing temperature.

The Alfa Laval Merco design is unique in making it possible to alter production settings while in operation, simply by adjusting the underflow draw-off valve in the discharge line.

To reduce maintenance costs and keep repair downtime to a minimum, the bowl is supported by a special overhead bearing cartridge with a very long service life. It is also quick and easy to replace when necessary.