PureNOx

Alfa Laval PureNOx has long been the choice for water treatment in Exhaust Gas Recirculation (EGR), a leading technology for Tier III NOx compliance. Today it’s available in an even more streamlined solution – PureNOx LS (Low Sulphur) – that supports both Tier III NOx compliance and Tier II fuel savings. PureNOx LS is optimized for EGR engines that operate on low-sulphur fuel. Upon request, solutions for use with high-sulphur fuel can also be tailored using PureNOx technology.

Optimization makes the difference

- Developed in close cooperation with MAN Energy Solutions

- Technology proven in thousands of hours of PureNOx operation

- Streamlined design, optimized for EGR engines using low-sulphur fuel

- 50% smaller centrifugal separator module

- More cost-efficient EGR

PureNOx LS reflects the global sulphur cap, which will lead to far more vessels sailing with low-sulphur fuel. Based on the latest engine maker guidelines, the system is optimized specifically to clean EGR bleed-off water in a setup similar to that of a bilge water system. The result is a smaller EGR water treatment system than ever before, but with the same reliable PureNOx technology. In turn, that means a more cost-efficient EGR solution. In addition, PureNOx LS has a unique strength compared to other systems on the market. It supports Tier II fuel savings with Eco EGR – and is the only water treatment solution that can.

Built on proven Alfa Laval PureNOx technology, PureNOx Prime is a bold step forward as Exhaust Gas Recirculation (EGR) matures. Smaller and leaner than its predecessor, it gives the front-running alternative for NOx abatement a sharper competitive edge.

EGR water treatment is coming into its prime

PureNOx Prime cleans the circulation water in an EGR process. EGR is an attractive alternative for compliance with Tier III NOx reduction demands, which entered into force in NOx Emission Control Areas in January 2016. EGR offers significant advantages, including a minimal footprint in the engine room and lower operating costs for most vessels compared with other NOx abatement technologies.

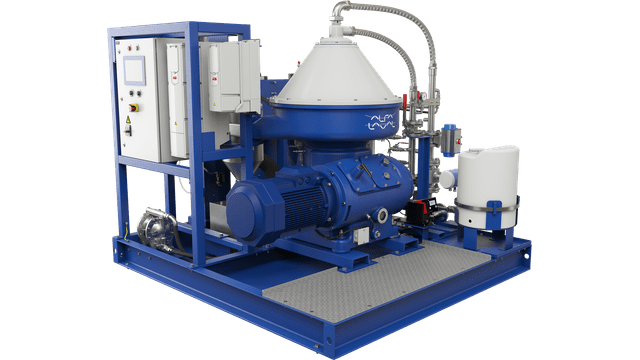

PureNOx Prime is a complete EGR water treatment system, developed in collaboration with MAN Diesel & Turbo. Using centrifugal separation, it protects the engine and the environment by removing soot and compounds from the fresh water in the EGR circuit. This water is recirculated in a closed loop, with additional water generated in the combustion process being cleaned and bled off in accordance with IMO criteria.

Specifically for use with low-sulphur fuel, PureNOx Prime is a commercialized solution providing:

- Peace of mind through proven engine protection

- Total assurance in meeting IMO discharge criteria

- Fully automated cleaning – communicates with the engine control system

- Cost savings in installation – modular delivery and easy connection

- Cost savings in operation – lower sludge volumes than other technologies

- Crew confidence – familiar high-speed separation technology

- Operating security via global service and spare parts supply

Compact, modular and easy to install, PureNOx Prime is part of a full EGR s;/ystem that forms an integral part of a MAN two-stroke marine diesel engine.

- EGR-specific high-speed separator(s) with ancillaries

- Overboard control sensors

- Sludge removal kit (option)

- Water buffer tank

- Control cabinet

EGR and PureNOx Prime

EGR offers these advantages over other technologies for reducing NOx emissions:

- Thousands of hours of proven operation at sea

- Smallest footprint

- Lowest operating costs

- Automatic response to engine load variations

- Immediate NOx compliance from start-up

Alfa Laval PureNOx: EGR water treatment with a difference

EGR has always been simple, compact and cost-effective but with the latest PureNOx developments, those advantages are even greater. PureNOx systems are now optimized according to the fuel sulphur level: low-sulphur (LS) or high-sulphur (HS).

Πως δουλεύει

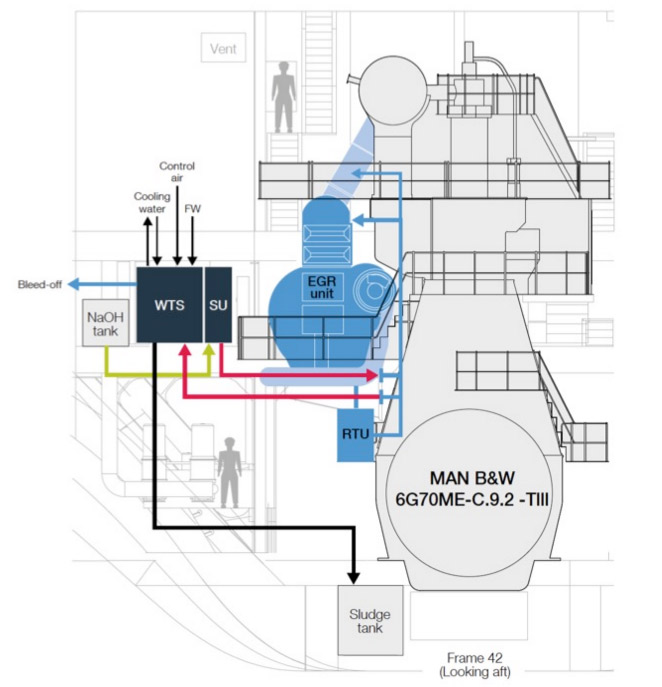

An Exhaust Gas Recirculation (EGR) system redirects up to 40% of the exhaust gas back into the engine’s charge air chamber, which lowers the oxygen content in the cylinder and increases the specific heat capacity. This reduces the combustion temperature, which suppresses the formation of NOx. The process is immediately compliant with Tier III and can be run at very low engine loads, with a fully automated EGR control system ensuring quick and correct response to load variations.

To prolong the service life of engine components, a wet scrubber in the EGR circuit uses fresh water to remove soot and sulphur oxides (SOx) from the recirculated exhaust gas. PureNOx Prime uses centrifugal separation to clean the soot and other exhaust gas compounds from this water, thus preventing them from accumulating in the scrubber and corroding the engine or EGR components.

Although the fresh water is recirculated in a closed loop, a certain amount of additional water is generated during the combustion process and must be bled off. PureNOx Prime ensures that this bleed-off water can be discharged in accordance with MEPC.184(59), monitoring and logging it in compliance with IMO directives.

PureNOx Prime also significantly reduces the waste volumes generated during EGR, which minimizes the costs for onshore sludge disposal. During maintenance of the water treatment system, the EGR system can be operated with reduced capacity.

PureNOx Prime is fully integrated into the EGR circuit.

Reducing NOx emissions from ship exhaust

Alfa Laval PureNOx water treatment system on board ensures full compliance with IMO and VGP regulations for NOx emissions. It also provides you with peace of mind, allowing free movement of your vessel worldwide and easy access to our global service network.