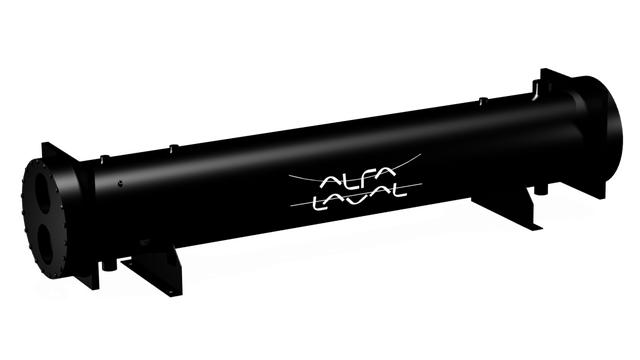

McDEW

The Alfa Laval McDEW is a condenser for seawater applications that use HCFC and HFC refrigerants at medium and high pressures (30 - 45 barg). Capacity range 15 - 1700 kW. PED/CE, ASME, EAC, SELO, DNV and other major marine approvals are available.

Alfa Laval McDEW series – for application using R407C refrigerant

The Alfa Laval McDEW is optimized especially for R407C refrigerant, however they offer flexibility in use of other refrigerants as well.

As the use of seawater can cause chemical corrosion, galvanic corrosion and erosion, the Alfa Laval McDEW is made of high-resistance materials. The design ensures easy inspection and cleaning of the condensers and assures that the water velocity is kept within the safety limits.

All models are provided with interchangeable anodes made of soft iron. The carbon steel components are sandblasted to protect against rusting, including the internal wall of the shell. The tubes are internally finned Cu/Ni 90/10, but alternative versions with Cu/Ni 70/30 are also available on request.

Options

- ASME, EAC, SELO, DNV and other major marine approvals availbale upon request

- Mounting feet

- Sight glass

Πως δουλεύει

All sea-water condensers are shell-and-tube heat exchangers. They have a primary fluid – normally a two-phase HFC refrigerant – flowing in the shell side, and a secondary fluid – seawater – running in the tube side.

Sea-water condensers are designed for use as one component in cooling systems that consist of compressor, condenser, evaporator and expansion valve. The two-phase refrigerant arrives at the condenser in vapour from the compressor at high temperature and pressure.

The refrigerant enters the condenser from the connection placed in the upper side of the shell and is distributed all over the shell thanks to an impingement plate. The contact of the high-pressure, hot-vapour refrigerant with the enhanced surface of the tubes – which are carrying the cooling water – causes the condensation.

When condensation process is complete, the refrigerant is slightly sub-cooled in order to avoid vapour bubbles reaching the expansion valve. This free condensation process, thanks to the high-performance tubes, ensures a lower condensing temperature which results in high efficiency of the cooling system.

The condensers have been carefully designed to take into account chemical corrosion, galvanic corrosion and the erosion effects caused by the use of sea-water. Attention has been paid to such aspects as the use of high-resistance materials, the possibility to inspect and clean the condensers as well as keeping the water velocity within safety limits.