Dairy processing

Driven by continuous innovation for over a century, Alfa Laval provides processing equipment that maximizes yield, facilitates easy cleaning, and minimizes waste at every step of dairy processing. Our components help you save on water, energy, and chemicals while meeting the strictest safety and hygiene standards. This way, dairies can make the most of every resource and create top-quality dairy products – with the flexibility and confidence to seize new opportunities in the market.

We help move dairy processing forward

More value from every drop

You can rely on Alfa Laval dairy processing equipment to get the most out of your milk – adding value at every step of your process. High-efficiency processing and gentle product handling secures better yield, reduced waste, and the highest possible product quality.

Furthermore, our innovative equipment designs and features enable extended production uptime with less time spent on cleaning and maintenance.

Built-in sustainability for the dairy industry

Reducing energy, water, and chemicals consumption is at the center of Alfa Laval innovations, helping promote your sustainability efforts. We provide unique solutions that significantly lower the power consumption in your dairy processing. Likewise, optimized cleanability lets you reduce the amount of time, water, and chemicals spent on Cleaning-in-Place.

Superior hygiene

Hygiene is critical in dairy processing. Every detail of Alfa Laval hygienic processing equipment is designed with a strong focus on hygiene, to facilitate cleaning and reduce fouling. This makes it easier for you to meet the industry’s strict hygiene and food safety standards – today and tomorrow.

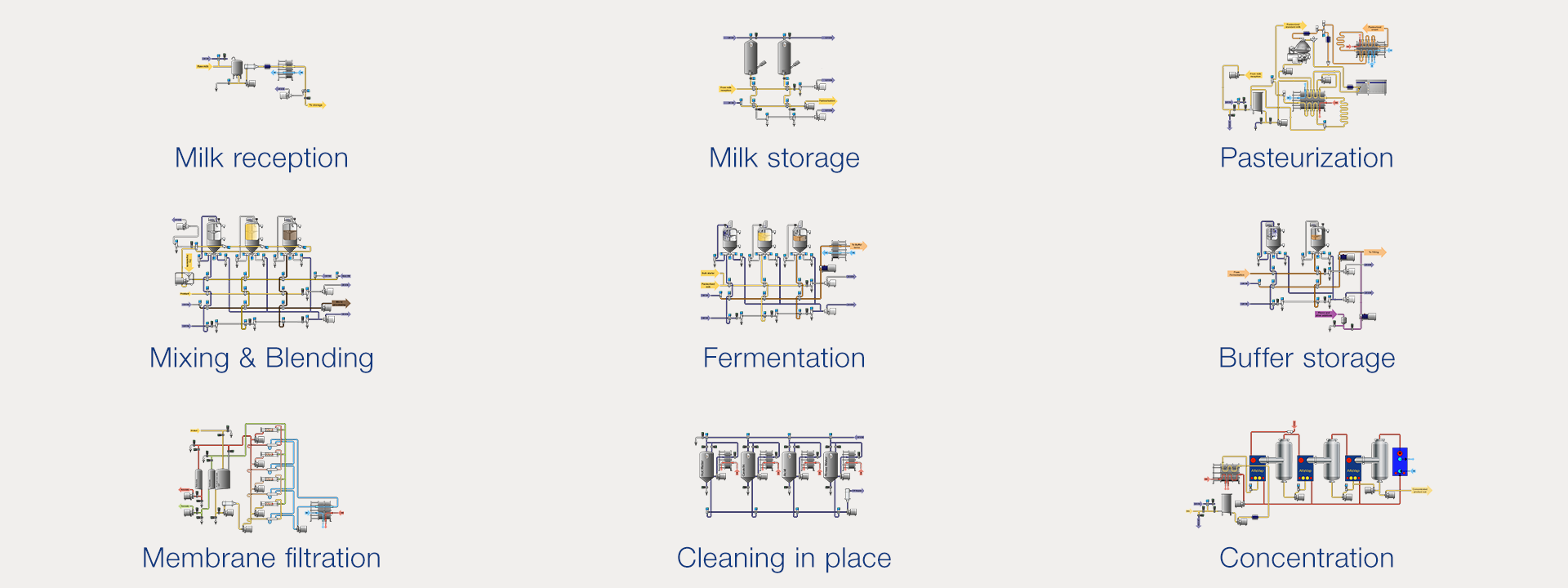

Optimizing every step in your dairy manufacturing process

From raw milk to finished dairy product, Alfa Laval components are designed to get the most out of every processing step. They help in maximizing yield, uptime, and product quality, while bringing power and water consumption to a minimum. Click on the button to view process steps and find highlighted technologies for dairy optimization.

An offering that helps capture the opportunities

Alfa Laval’s global and local presence, comprehensive offering and world-class support ensure we can help you capture the opportunities of today and tomorrow. There are challenges and tremendous opportunities for those who can respond with flexibility and efficiency. To ensure our hygienic components support these challenges and provide the leading support for dairy applications, we strive to address these four key industry needs:

- Supplying products to consumers at a competitive price

- Getting the most from raw materials

- Reducing waste and emissions

- Delivering safe and hygienic products

Optimizing every process

Alfa Laval’s comprehensive range of innovative sanitary components are key building blocks in dairy processes such as, milk reception and storage, pasteurization, fermentation, separation and concentration and cleaning in place are important to dairy applications.

Why choose Alfa Laval?

- Proven reliability

- Increase energy efficiency

- Achieve the low operating costs and low total cost of ownership required for good margins in competitive markets

- Ensure gentle and effect heat treatment and pumping, essential for achieving optimum quality and yield

Product catalogue

Spare parts catalogue

Brochure: At the heart of dairy

360° Service Portfolio

Alfa Laval hygienic equipment is backed by the Alfa Laval 360° Service Portfolio to extend performance.

Danish Dairy and Food Industry

Ten top tips collection

Hygienic equipment brochures

Find the information you need about our equipment for hygienic use.

Animations

Visit the animations site and take a look inside a product to see and understand how it works.