Algae processing

Is your organization working on research or commercial activities involving the harvesting of algae ponds or fermenter tanks? Are you looking for reliable process equipment? Separation is central to algae harvesting, and Alfa Laval has been providing separation solutions for 130 years. Alfa Laval offers a number of proven process solutions and can help you address some of the challenges you meet in producing biofuels from algae.

Putting proven technology to new “green” uses

Many experts view biofuel based on algae as a viable alternative to fossil fuels – although attempts to turn idea into reality are relatively new. But Alfa Laval has delivered equipment for macro- and microalgae for decades. We offer a number of proven solutions and can help you address some of the challenges you meet in producing biofuels from algae. Alfa Laval also provide solutions for producing algae-based products for pharmaceuticals, nutrition products and more.

Let us help you with your pilot project

Alfa Laval is currently involved in numerous pilot projects around the world – so we’re well equipped to help you with yours. One example is a Utah State University project tasked with developing and demonstrating low-cost, large-scale, commercially viable technologies to produce fuel from algae.

Another involves producing high-performance algae-based products for use in the pharmaceutical, nutrition, aquaculture, animal feed and fuels market.

Algae separation: how it all comes together

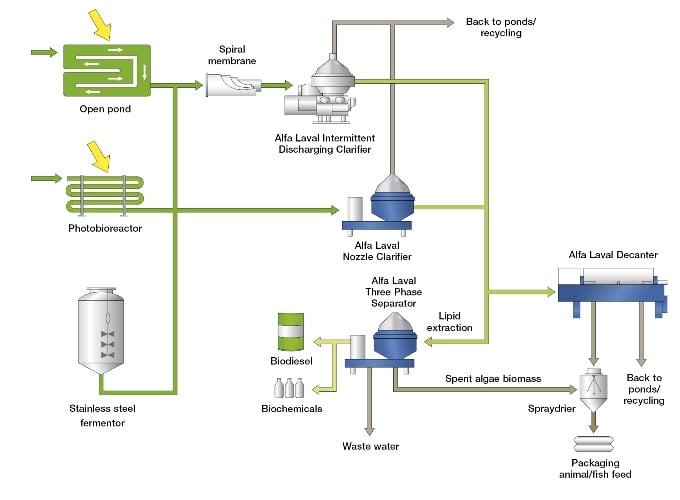

The chart shows various roles Alfa Laval equipment can play at different process stages after algae has been pumped from an open pond, photobioreactor or fermenter

Selection of equipment depends on capacity required and product characteristics such as viscosity, solids content, pH value in the fermentation broth and limpidity.

Our solutions

High-speed separators

A number of Alfa Laval separators are suitable for use in the harvesting stage to separate the algae cells from the liquid growth media. These include both intermittent and continuous discharging separators for capacities ranging from a few litres to hundreds of cubic meters.

Decanters

Alfa Laval decanters are perfect for dewatering the algae biomass slurry after it has been processed in a separator, resulting in a concentrated product. Again, we have equipment suitable for pilot plants up to commercial scale facilities.

Membranes

Alfa Laval membranes can be employed to enhance the separation performance, for example in the pre-concentration step.

Evaporators

Alfa Laval evaporators can ideally be used for concentration of products, for example oils, produced by algae.