S and P Flex

The S and P Flex range of separator systems for fuel oil and lubricating oil combines the unique strengths of Alfa Laval's S separators and P separators with a modular concept for truly flexible supply.

Essential protection and high flexibility in one

- Tailor to specific needs – flexible system with range of options

- Proven performance – the world’s best-selling separator for fuel and lube oil

- Cost-effective investment

- Space-saving modularized footprint

With the Alfa Laval S and P Flex range you can tailor your separator system to your specific performance and space requirements. The advanced S separator uses Alfa Laval ALCAP™ technology to adjust to your oil, maximizing protection and fuel economy. The P separator is a high-performance alternative for oils with fewer process issues. The system is built on a low-wear mechanical platform that further reduces lifecycle costs.

The S and P Flex range combines essential protection with high flexibility, letting you design and construct your Alfa Laval separator system as you see fit. Incorporating the advanced efficiency of the newly updated S separator and the affordable simplicity of the P separator, it lets you choose the separation system that best meets your performance needs and available space.

- S separator

- P separator

- Low-wear mechanical platform

- Flexible supply

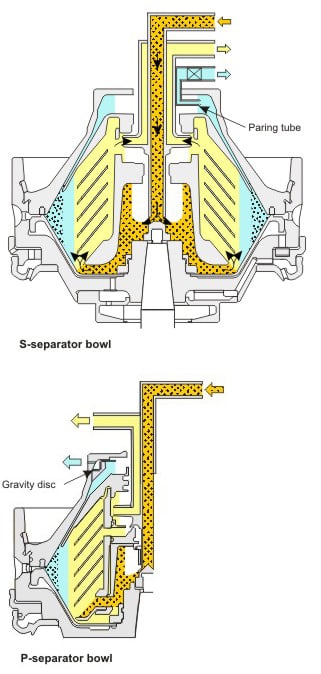

The S separator

The S separator is the world’s best-selling and most efficient separator for fuel and lube oil. Using Alfa Laval’s unique Alcap technology, it automatically adjusts to the nature of your oil, giving you thorough protection and maximum economy from your fuel.

Today’s S separator contains enhancements that further increase its efficiency. Smart modifications in the disc stack, including an increase in separation area, allow up to 20% more flow with retained separation performance. This lets you process the same amount of oil with a smaller separator.

Additional features, including a more robust drive system, add to the S separator’s reliability and further reduce lifecycle cost.

The P separator

The P separator shares many features with the S separator, but it is designed for well-defined oils with fewer but vital process issues. Instead of the more refined Alcap technology, it has a manually set gravity disc or clarifier disc in the separator bowl.

The result is a separator with the same high performance, but one that is more suitable for lubricating and marine diesel oils, as it does not automatically compensate for density fluctuations.

A low-wear mechanical platform

S separators and P separators are built on a low-wear mechanical platform that features CentriShoot and CentriLock.

The CentriShoot discharge system, which greatly reduces sludge volumes, has a fixed discharge slide that flexes gently at the edges to expose the discharge ports.

The CentriLock bowl-locking system uses a lightweight, non-threaded snap ring that snaps in and lifts out with no more than an Allen key.

Both of these features prevent metal-to-metal wear. As a result, they minimize the risk of bowl replacement and significantly reduce lifecycle cost.

Flexible supply

The Flex range concept provides flexible options for the delivery of S separators and P separators:

- Flex system

A separator with ancillaries as block components provides full say over the use of space in the engine room. This option allows local modularization or do-it-yourself assembly. - Flex modules

Customer-specified modules can be created using a wide variety of skids and machine blocks. Modular components can be delivered separately and assembled on site, which makes even larger systems easy to retrofit. Mixed modules are also possible for the simultaneous treatment of different mineral oils.

All deliveries feature the modular and easy-to-use EPC controller, which is based on standard supply and connects via Ethernet or bus communication to onboard automation systems.

Watch the movie fuel cleaning onboard

Download

Related product

Service by exchange

- Time-saving service of Vertical Driving Device (VDD)

- VDD exchanged for a reconditioned unit

- Gives low OPEX and full peace of mind

- Performed on board during Overhaul service

- Part of a Performance Agreement

How it works

Separator technology and the ALCAP™ advantage

High-speed centrifugal separators clean marine fuel by removing water and particulate matter. Traditional separator designs use a gravity disc that is manually adjusted depending on the density of the specific fuel being used.

Alfa Laval’s ALCAP™ separator technology eliminates the gravity disc to allow for automatic adjustment to fuel density. In multifuel operations, ALCAP™ provides the advantages of uninterrupted operation, improved fuel efficiency, and maximum separator performance and engine protection.

The Alfa Laval S separator, with ALCAP™ technology, features software that allows you to set parameters in the process controller. This lets you combine heavy fuel oil and lubricating oil treatment in a single separator. After centrifugal separation, the clean oil is continuously pumped away. Water and sludge accumulate at the bowl periphery.

A water transducer in the clean oil outlet measures capacitive resistance and signals changes to the EPC60 control unit, which masterminds the system. Depending on the water content, the EPC60 either opens the drain valve or expels the water during sludge discharge.

The CentriShoot discharge process uses a patented slide that eliminates metal-to-metal wear and minimises loss compared to other systems.

The Alfa Laval P separator is designed for well-defined oils with fewer process issues. The separator bowl has manually set gravity discs to deliver high performance but does not automatically compensate for process fluctuations. The separator bowl can be configured as a purifier or as a clarifier.

- A purifier removes solids and water from oil.

- A clarifier is removing only solids (no water) from oil.

Separation Efficiency Upgrade

Protect your engine and your business with the Alfa Laval Separation Efficiency Upgrade. This service offering upgrades your existing Alfa Laval S separator with the latest generation Alfa Laval disc stack, improving separation efficiency by up to 30%. Readily available and quickly installed, the upgrade boosts your engine protection to the highest level - and is the fastest way to get CFR-certified performance.

Alfa Laval's Adaptive Fuel Line

Alfa Laval’s Adaptive Fuel Line will provide engine protection and energy efficiency while keeping you in compliance with new regulations.

Watch the movie fuel cleaning onboard

Flow optimization of the separator feed

Improved separation and energy savings beyond the pump

Whitepaper: The importance of lube oil cleaning

Eager to understand more about lube oil cleaning? Our whitepaper gives you a comprehensive overview of the technologies available and acts as a guide to choosing the best one for your application.

Experience the benefits of high-performance lube oil cleaning

The quality of your lube oil determines equipment lifetime and levels of productivity. Cleaned lube oil maintains its quality over time and is therefore essential to a healthy, trouble-free process.