Bio-based chemicals

Chemicals and materials from various biomass sources play an important role when it comes to reducing our dependence on non-renewable resources. Trees, plants, crops, algae, bacteria and biological waste can be used in their different shapes and forms to produce a wide range of bio-based chemicals, fuels, products and intermediates.

Alfa Laval can help you with efficient separation of fermentation broth and harvesting, purification after pre-treatment, concentration of sugar streams and lignin, as well as treatment of wastewater and zero liquid discharge. With our wide range of efficient heat transfer and separation solutions, we are here for whatever support your bio-based processes require.

Cellulosic sugars and ethanol

The production of sugars and ethanol from cellulose require additional separation steps compared to traditional sugar and first generation ethanol production. Alfa Laval high speed separators can be used to remove lignin content after pre-treatment as well as for yeast removal while evaporation systems are used to concentrate sugar, lignin and wastewater streams to secure optimal process conditions at a high efficiency and water reuse to minimize fresh water intake.

Bioplastics

Biodegradable plastics from renewable resources are the future for sustainable virgin plastic production. Alfa Laval has the experience to remove cells or bacteria from the fermentation broth for PLA (polylactic acid) as well as PHA (polyhydroxyalkanoates) production using high speed separators. This type of separation utilizing the same technology has been used in the biotech and pharma industry since early 1980s.

Pyrolysis

Pyrolysis is a thermal process in which materials decompose at an elevated temperature in an inert, oxygen-free atmosphere. Virtually any source of biomass or waste can be used for pyrolysis, making this an increasingly interesting solution for the renewable and recycling market. It can be used to make oil from, for example, wood and sawmill waste, used waste tyres or mixed plastics recycling. Depending on the raw material, other gaseous and solid products can also be generated to provide additional value.

Oil obtained from pyrolysis requires removal of moisture and suspended particles before being converted into value-added products in downstream processes. Alfa Laval’s proven high-speed separation technology efficiently cleans pyrolysis oil in one single operation, simultaneously removing both water and particles. We also offer an extensive portfolio of plate heat exchanges for related cooling duties of the pyrolysis process.

Tall oil production

The declining paper market is putting pressure on pulp mills to find new ways of maximizing profitability. For many, this has meant creating entirely new and sustainable revenue streams, taking advantage of the by-products created in the mills’ processes. Rather than seeing them as waste, these by-products contribute to profitable side businesses selling turpentine, lignin and, above all, tall oil.

Today, Alfa Laval’s proven separation technologies are a vital component in many tall oil recovery systems. They make it possible for pulp mills to increase the yield of their pulp oil recovery, while also improving the product quality and even the sustainability of their operations.

HVO pre-treatment and Zero Liquid Discharge

Vegetable oils from soybeans, rapeseed, tallow and used cooking oil are raw materials in the production of renewable diesel and jet fuels. While hydrogenated vegetable oil (HVO) can be produced using traditional refinery processes, it requires a pre-treatment unit (PTU) upstream in the process. This pre-treatment involves water-washing steps followed by a high speed separator for efficient separation of the wash water from the oil and minimum losses of the feedstock. Alfa Laval can supply complete pre-treatment units together with a Zero Liquid Discharge solution, ensuring water reuse for the washing steps.

Our solutions

High speed separation solutions

For centrifugal separation, Alfa Laval offers ideal options for any type of bio-based chemical process. Matching the right equipment with the specifics of your process, your organism selection, your feedstock and your fermentation medium is absolutely crucial to the success of your production. We can support you with separation solutions to suit every possible combination of circumstances and requirements.

Evaporation solutions

For evaporation, Alfa Laval offers complete systems optimized for your specific circumstances. For example, is low capital outlay your priority? Or is it more important to minimize steam consumption and achieve the lowest possible operating costs over the long term? Either way, we can design the system that best answers your needs.

Zero Liquid Discharge

Alfa Laval Zero Liquid Discharge (ZLD) systems are robust, compact solutions designed for the absolute minimization of liquid discharge in a wide range of industrial waste applications. ZLD systems optimize the efficiency of your water consumption via a combination of thermal solutions and separation technology, with the AlfaFlash evaporator at the core of the set up.

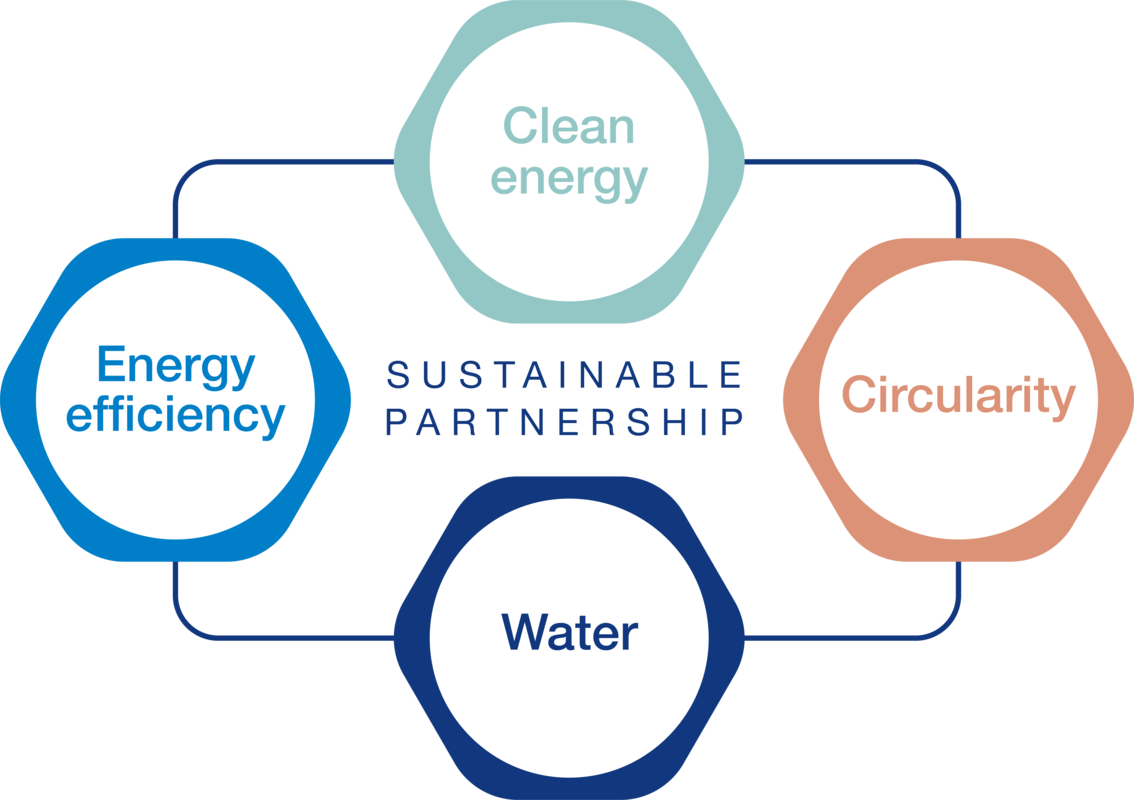

Energy efficiency

Clean energy

Sustainable partnership

Contact us to learn more

Contact us today for more information about our sustainable solutions